Upgrades

Press Upgrades and Structural Modifications

At RSM Technology, we offer more than just repairs and maintenance—we provide comprehensive upgrade and structural modification services for hydraulic and mechanical powder compaction presses. Our engineering team specializes in enhancing the performance, functionality, and adaptability of your existing equipment, ensuring it meets the evolving demands of modern production.

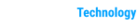

As manufacturing technologies advance, older machines often require more than a basic retrofit to stay competitive. That’s why we go further—designing and implementing structural upgrades that give your presses new capabilities and greater operational flexibility. From frame reinforcements to stroke adjustments and bed plate redesigns, we can modify your press structure to better suit your specific applications and product requirements.

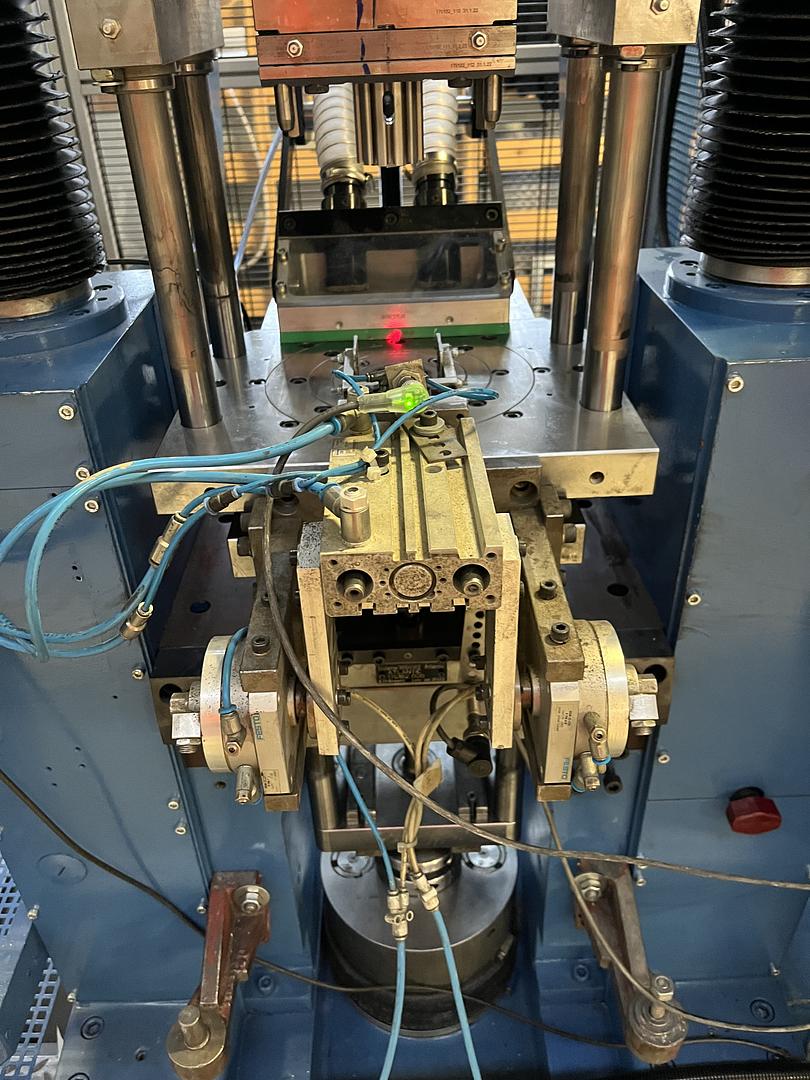

These structural modifications are tailored to your machine’s original design and current condition. We begin by analyzing your production goals and evaluating the mechanical limitations of your equipment. Our technicians then engineer and execute modifications that optimize performance—whether that means increasing press force, improving part accessibility, enhancing tool alignment, or integrating custom motion profiles.

Contact Our Retrofitting Experts

Every upgrade is carried out with full attention to quality and regulatory compliance. We ensure that all structural changes meet CE and ISO standards, and we validate mechanical integrity through rigorous testing procedures. In many cases, clients choose to combine upgrades with a full retrofitting package, resulting in a fully modernized and customized press that is more efficient, safer, and easier to operate.

Our deep experience with Dorst press systems and other powder compaction equipment makes us a trusted partner for clients across Europe and beyond. We have successfully delivered structural upgrades for press models ranging from compact table units to large-tonnage machines—always tailored to the specific needs of our clients' production processes.

Whether you need to adapt your press to a new part geometry, increase press capacity, or improve the ergonomics of machine operation, our team can help. We handle each project with precision, technical rigor, and full transparency from start to finish.

If you're looking to unlock new potential from your existing press systems, contact us today. Send us your inquiry using the form below and we’ll respond promptly with a tailored solution for your machine.